Monitoring for Asbestos

Asbestos monitoring has the power to save lives, but it’s vital that we maximize accuracy and minimize risks.

By: Tim Turney, Contributor

More than 1 million U.S. workers in construction and general industry are at risk of asbestos exposure.[1] Left alone, the material is not harmful but, once disturbed or disintegrating, it can release asbestos fibers that infiltrate and progressively damage the lungs. The damage results in multiple health defects, such as the lung disease mesothelioma—a cancer that can take up to 20 years to develop, proving fatal within five years or less.

More than 1 million U.S. workers in construction and general industry are at risk of asbestos exposure.[1] Left alone, the material is not harmful but, once disturbed or disintegrating, it can release asbestos fibers that infiltrate and progressively damage the lungs. The damage results in multiple health defects, such as the lung disease mesothelioma—a cancer that can take up to 20 years to develop, proving fatal within five years or less.

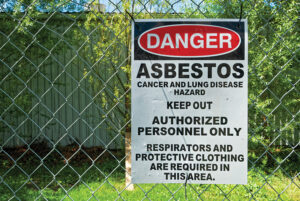

Although asbestos has been banned in more than 60 countries, it is not completely banned in the U.S.[2] It can still be found in older homes and industrial properties and continues to be used in products such as gaskets, friction products, roofing materials and fireproofing materials. However, whenever asbestos is known to be present, it is a legal requirement for licensed contractors to remove the hazardous material following strict regulations and guidance to limit the potential release of dangerous, airborne fibers. The guidance, depending on national practice, typically includes personal air sampling and/or static air sampling, to ensure that there is no exposure during remediation work or during the cleaning and clearance processes at a removal site.

Understanding how to maximize asbestos monitoring accuracy and minimize risks can help to save lives.

Training & Licensing Requirements

Discrepancies in sampling and analysis procedures; limitations in personal protective clothing; and insufficient cleaning before a clearance pass can hinder accuracy and increase risks. The U.S. Environmental Protection Agency (EPA) requires that professionals performing asbestos repair and removal are thoroughly trained and accredited. Trained and licensed professionals should use the proper equipment and approved respirators, gloves, overalls and other protective clothing.

Discrepancies in sampling and analysis procedures; limitations in personal protective clothing; and insufficient cleaning before a clearance pass can hinder accuracy and increase risks. The U.S. Environmental Protection Agency (EPA) requires that professionals performing asbestos repair and removal are thoroughly trained and accredited. Trained and licensed professionals should use the proper equipment and approved respirators, gloves, overalls and other protective clothing.

In addition, there are usually strict local, state and federal requirements for asbestos removal and disposal that professionals in the field must follow. Checking with the local air pollution control board, the local agency responsible for worker safety and the Better Business Bureau can provide information about the trustworthiness and expertise of the firm, for example, by shedding light on any previous safety violations.

Equipment: Select, Used & Maintain Correctly

The National Institute for Occupational Safety and Health (NIOSH) Method 7400 is a widely-used method for measuring airborne asbestos, involving sampling with a flow rate from 0.5–16 L/min. Using this method will ensure compliance with the limits set by NIOSH, OSHA and other regulatory agencies for area samples, as well as personnel monitoring. Modern pumps can do timed or volume-based runs to achieve better result accuracy. However, reading the manufacturer’s handbook thoroughly before using the equipment can ensure correct use and allow for optimal feature use.

The National Institute for Occupational Safety and Health (NIOSH) Method 7400 is a widely-used method for measuring airborne asbestos, involving sampling with a flow rate from 0.5–16 L/min. Using this method will ensure compliance with the limits set by NIOSH, OSHA and other regulatory agencies for area samples, as well as personnel monitoring. Modern pumps can do timed or volume-based runs to achieve better result accuracy. However, reading the manufacturer’s handbook thoroughly before using the equipment can ensure correct use and allow for optimal feature use.

Ensuring air sampling pumps have good flow control can ensure accurate sampling. Additionally, selecting an air sampling pump that has a good Ingress Protection (IP) rating will allow for easier decontamination, a process nearly as important as removing asbestos correctly in the first place.

Asbestos does not only pose a threat to trade workers, but also those they encounter, should invisible yet lethal asbestos particles stick to PPE and tools. Following stringent cleaning regimes can protect workers and their colleagues, family and friends. All equipment must be thoroughly decontaminated to ensure there is no subsequent exposure or spread of asbestos, including inner parts of the machine where fine airborne asbestos fibers may have penetrated.

Choosing a high flow pump with a smooth body finish, free from small crevices, will allow for safer decontamination and cleaning. Modern air sampling pumps can also be monitored remotely with Bluetooth via a mobile app to check the sampling status, thus saving time checking pumps.

Basic Awareness Training is Not Enough

Asbestos monitoring has the power to save lives, but only when carried out correctly. Basic awareness training is not enough. Additional consultancy and training should always be acquired before carrying out asbestos removal to achieve the required level of competence and help keep more workers safe.

Tim Turney is Global Marketing Manager at Casella and graduated as an engineer from Queen Mary and Westfield in London. Since starting at Casella in 1998, Tim has been involved in the acoustics and air sampling industry, specializing in measurement and instrumentation technologies.

[1] https://www.asbestos.com/occupations/construction-workers/

[2] https://www.mesothelioma.com/lawyer/legislation/asbestos-ban/

Share on Socials!

Fixed Gas Detection: Issues and Answers

Basewell – Guardian2 Case Study

Avoiding Prolonged Noise Exposure

Leaders in Industrial Hygiene

Council for Accreditation in Occupational Hearing Conservation (CAOHC)

Subscribe!

Sign up to receive our industry publications for FREE!