Revolutionizing Workplace Noise Monitoring: Svantek's Validation Tool

Personal noise monitoring is rarely a supervised sampling event for the duration of the dosimetry session. Health and safety professionals rely on the integrity of their workers, and their sampling strategy to collect representative data. This approach has limitations. Mechanical shock, noise artifacts, and dosimeter removal are all events that can occur and can lead to unrepresentative exposure data.

Analyzing and editing such data has been a cumbersome task for the safety professional. Hours of reviewing data sets and discussions with workers about their activities have made the data validation process difficult and unrealistic. These same obstacles make the data analysis process an even more difficult task for tech level positions.

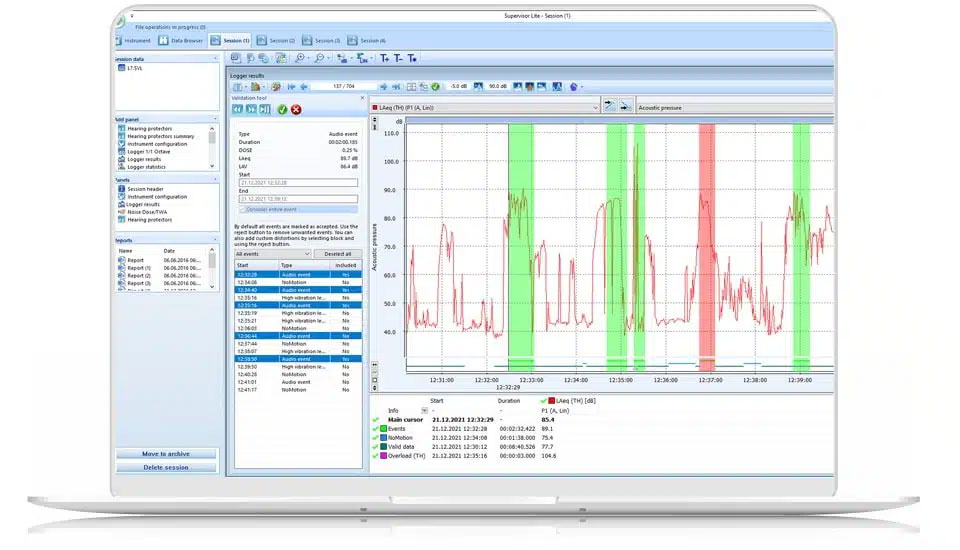

To address this need, the acoustical engineering team at Svantek created the Validation Tool in the Svantek Supervisor and Supervisor Lite software. The Validation Tool allows the safety professional to easily review flagged data points within the data set to determine if the events were actual exposures, or invalid occurrences. This feature has created an efficient and reliable set of checks and balances within the Svantek dosimetry system that provides integrity to the data analysis process. The feature also allows tech level users assistance in the data analysis portion of the exposure assessment; freeing up the supervising industrial hygienist to accomplish other tasks.

Data validation should not be confused with data removal. Though the safety professional may choose to remove unvalidated data, the purpose of the Data Validation is to simplify the process of identifying events in the data set that need to be either accepted or rejected. In a peer reviewed application note, sampling data was assessed with and without the Validation Tool. The Validation Tool was able to flag data caused by mechanical shock events from the dosimeter being dropped, and from banging against the worker’s hard hat. Additionally, a short no motion period when the dosimeter was removed by the worker was flagged and all this data was easily excluded from the final exposure analysis. What would have initially led to the worker being included in the hearing protection program was able to be reanalyzed without the non-acoustic events, and the worker was found to be below the threshold for action.

Events such as the ones mentioned invalidate data because the dosimeter either over calculates (mechanical shock), or undercalculates (dosimeter removal) the overall exposure to the worker. Both scenarios pose different threats; underestimating the exposure leaves the worker subject to noise induced hearing loss if the proper hearing protection is not issued. Overestimating the exposure consumes time and resources that would otherwise be allocated to more realistic threats. Whichever scenario it is the safety professional faces, it is imperative that they address it with confidence and efficiency. Data validation can be the tool that helps you and your team properly address these obstacles.

OHD is proud to be the U.S. Master Distributor for Svantek’s line of noise and vibration monitoring devices. Svantek is a leading manufacturer of sound and vibration measurement instrumentation and software for professional use in the field of occupational noise, human vibrations, environmental noise monitoring, and building and ground vibrations.