Today, Camfil Air Pollution Control (APC) proudly unveils its latest dust collection controller, the Gold Series Timer (GST). This is a user-friendly and easily applied solution for pulse-jet cleaning control of industrial dust collection systems including baghouse designs. The GST stands out with its pulse output modules, which are seamlessly expandable to accommodate various solenoid…

Read More >>How personal air sampling pumps can protect employees from unseen dangers By: Tim Turney, Contributor Many industrial workers are exposed to some amount of potentially hazardous dust, fumes, gasses or vapors every day at their place of work. The latest statistics by the U.S. Department of Labor (DOL) found that in 2021, 551 fatalities were…

Read More >>Editor’s Note: The following article first ran in IHW’s sister publication, Packaging Technology Today, in 2023. For the original article, go to https://tinyurl.com/bdbkb6f8 . What’s so dangerous about dust? Put simply, dust is the largest contributor to poor indoor air quality (IAQ), and poor IAQ leads to health problems and combustible dust incidents. Airborne metal,…

Read More >>Silica: Stealing Lives for Centuries Approximately 2.3 million professionals face exposure to crystalline silica at work. In 2016, OSHA updated the exposure regulations for silica for the first time since 1971. Two years later, the National Institute for Occupational Safety and Health (NIOSH) reported on the largest cluster of black lung disease among active coal…

Read More >>Jeramy Slaunwhite P.Eng, Chief Technical Officer, REMBE® Inc. Many industrial facilities handle combustible particulate material which pose fire and explosion hazards. Managing combustible dust hazards is critical to ensure the safety of the plant personnel and operations. In order to effectively manage combustible dust hazards they must first be identified and understood. A dust hazards…

Read More >>“NFPA 654 is a great place to start when taking steps to identify hazards and developing action items designed to reduce risk within a facility handling explosible or combustible materials. There are NFPA codes specific to an industry, but NFPA 654 covers all other processes where combustible material is present.” Fauske & Associates, LLC., 1-877-328-7531,…

Read More >>A safety expert walks agricultural and food processing companies through dust hazard analysis, NFPA 61 compliance, and leading options to address the risk of combustible dust explosions For owners and operators in the agricultural and food processing industries, January 1, 2022, was the deadline for completion of a dust hazard analysis (DHA) for existing facilities…

Read More >>By: Rachel Krubsack, Contributor In January 2023, OSHA issued a revised Combustible Dust National Emphasis Program (NEP), CPL 03-00-008, which replaces its March 2008 directive. Like its predecessor, the revised NEP contains policies and procedures for inspecting workplaces that generate or handle combustible dusts; and for determining whether such workplaces have addressed fire, flash fire,…

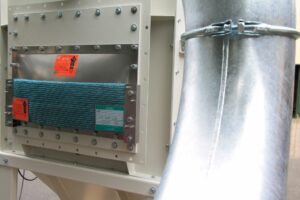

Read More >>Comprehensive combustible dust explosion protection does not necessarily have to be expensive or complicated. An innovative technology makes it possible to divert the shock wave and flames of an explosion in a controlled manner. The result: the required safety area is reduced, so valuable, usable area is increased and personnel/equipment are protected from the explosion’s…

Read More >>By: Ashley Griesenbrock, CIH, CSP, Contributor You may think of “dust” as just a nuisance in the workplace; however, dusts and fumes in the workplace can pose a significant hazard to employees and even equipment. Dusts and fumes can be found in almost any industry or workplace setting. Dusts are defined as mechanically produced solid…

Read More >>Leaders in Industrial Hygiene

Council for Accreditation in Occupational Hearing Conservation (CAOHC)

Subscribe!

Sign up to receive our industry publications for FREE!