2023 Safety Study: Training, PPE, Tech, Safety Culture & More

Modern workplaces are continuing to adopt technology for safety-related tasks at a significant level. (photo courtesy Adobe Stock Images)

By: Barbara T. Nessinger, Editor-in-Chief

In 2022, the RDG Media team, with the help of Market Research Support Consultants, LLC, conducted a study to understand the current and expected usage of various products and services as they applied to safety and material handling. The 2023 Safety Study’s results have helped to provide detailed information on these aspects. The key objectives for this study covered three areas, including understanding the importance of frontline supervision safety tasks; understanding purchase plans and spending, general products and services, and technology focused products and services; and understanding respondents’ purchase influence and demographic profile.

Safety Culture, Labor & Supply Chain: Good News

Everyone has been somewhat affected by fluctuations in the labor market. The ongoing and wide-ranging labor shortage has negatively affected a majority (76%) of the respondents, to various degrees, with 41% saying it put their operations behind less than three months; 12% three-six months; 3% six-twelve months; and 24% reporting it had no impact at all.

The study found that the shortage had a lesser effect on companies’ safety cultures. It also identified the strategies managers are using to maintain company culture and standards of safety:

The study found that the shortage had a lesser effect on companies’ safety cultures. It also identified the strategies managers are using to maintain company culture and standards of safety:

- Less than half of respondents reported some type of impact

- 24% said that existing staffers are working overtime to maintain desired levels

- 18% of the companies involved are paying outside vendors

- 9% have made additional hires

- 6% have made reductions or changes in company standards on safety, due to an inability to keep up with the current workflow

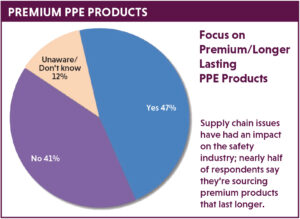

Supply chain issues have also naturally had an impact on the safety industry, and nearly half (47%) of respondents stated that premium products that last longer have been a focal point when sourcing PPE. This clearly sends the message that PPE made to last and stand up to daily wear-and-tear (where applicable) is an important consideration. (See chart “Premium PPE Products”)

How are they dealing with the supply challenges? Twenty-six percent use paid outside vendors to secure the necessary materials and supplies; 24% are having existing staff work overtime to do so; and 3% have hired additional workers to deal with the problem.

Safety Training: Challenges & Methods

Training employees remains paramount to safety culture, and employers utilize a variety of ways to get their safety messages across. More than seven-in-10 respondents plan to educate new workers through communication programs with a focus on increased training as well.

Training employees remains paramount to safety culture, and employers utilize a variety of ways to get their safety messages across. More than seven-in-10 respondents plan to educate new workers through communication programs with a focus on increased training as well.

Nearly nine-in-10 respondents noted they rely on a combination of vendor support training and inside development for implementing safety training. Interestingly, only one-in-10 are currently using artificial intelligence (AI) as part of that safety training implementation. Only a third of study participants said AI is used by their companies, but 12% plan to use it within the next year. Thirty-five percent have no plans to use it, and 32% are unaware of what AI training is. This is a space that might be explored and see more growth in the next few years, however.

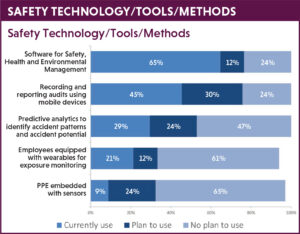

Two-thirds of respondents currently use software for safety, health and environmental management, followed by just under half of respondents currently recording and reporting audits using mobile devices. (See chart “Safety Technology/Tools/ Methods”)

Some of the challenges facing new employee training include a lack of knowledge at the onset. For example, when asked the question: “What challenges/trends do you experience when training and/or working with younger new hires such as Millennials or GenZ,” approximately four-in-10 respondents stated that new hires are not knowledgeable of new gas monitoring options and traditional gas monitoring options, including bump testing and calibration methods.

As might be expected–given the various industries and facility types involved—findings about when, how and how often safety training is done yielded a variety of answers in the 2023 Safety Study. (photo courtesy Adobe Stock Images)

As might be expected–given the various industries and facility types involved—findings about when, how and how often safety training is done yielded a variety of answers:

- 29% of respondents said their companies do safety training during onboarding

- 7% said retraining is required after an incident or unsafe situation occurs

- 5% conduct safety training twice a month

- 15% do it once a month

- 6% do safety training once a year

When it comes to new workers, more than seven-in-10 (79%) respondents educate them through communication programs and increased training—71% through increased training alone, 35% using additional signage and 24% with additional visual floor markings.

Gas Detection/Monitoring

Gas Detection/Monitoring

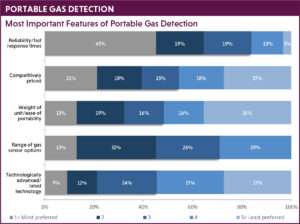

When queried about gas detection and monitoring, just over one-third of respondents state that the Safety Department is responsible for establishing and maintaining Grade D compressed breathing facilities. More than half (52%) of respondents say they currently use portable gas detection. Among those that currently use portable gas detection, “reliability/fast response times” are the highest ranking features when purchasing portable monitors. And leadership counts in this area: One-third of respondents state the senior leadership of their organization is “very involved” when implementing new gas monitoring processes or purchasing new equipment. Approximately four-in-10 respondents have had some type of involvement in fixed gas monitoring. (See chart “Portable Gas Detection” )

Importance of EHS Teams and ESG Overlap

Companies overwhelmingly rely on their EHS experts to help mitigate accidents and increase worker safety. A full two-thirds of respondents state that the EHS team in their organization is seen as “a strategic enabler for commercial growth and operational continuity.” Three-quarters of respondents state that real-time risk management for both works and assets is extremely/very important.

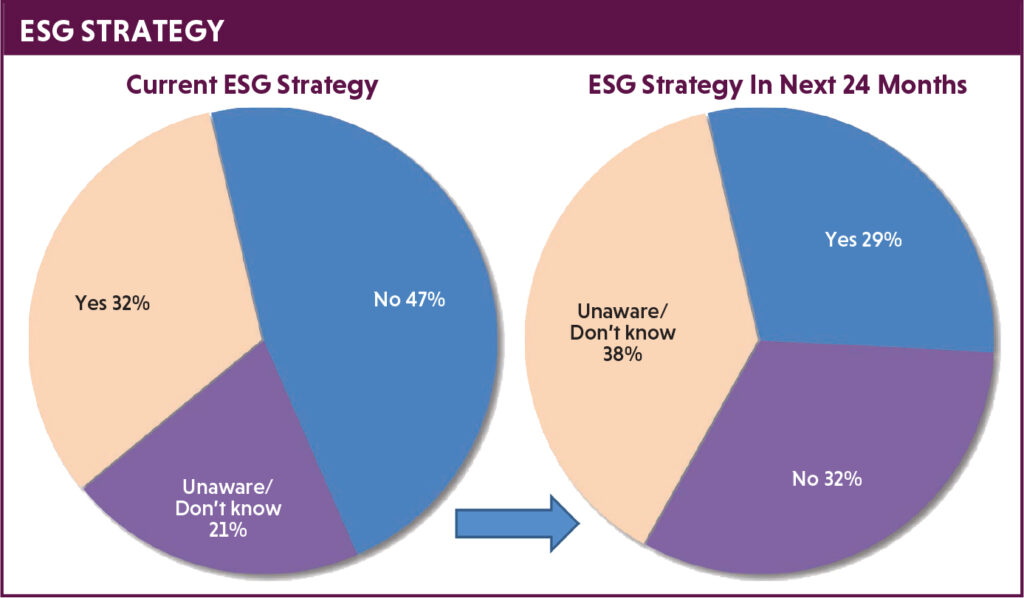

Not all companies are involved in Environmental, Social & Governance (ESG) strategies, however. Only one-third of respondents state that their company is actively involved with an ESG strategy. Of those that are not actively involved, just over one-quarter of respondents believe they will be in the next 24 months. (See chart “ESG Strategy”) Given the natural overlap of ESG and EHS, this is one area that is predicted to see growth in the future.

Positive Outlook on Safety

Overall, respondents value safety, training and the importance of maintaining a safety culture. Depending on each company’s individual needs—and the challenges of labor shortages and supply chain interruptions—how they implement safety and training differs, including the strategies managers use to maintain company safety culture. The good news is that EHS experts have an increasingly large role to play in ensuring workers have the tools and training they need to stay safe—and remain productive.

Share on Socials!

Hazard Training: Safety Data Must Be 24/7

Aerosol Science Significance for COVID

Breathing Safely: Simplifying Complex Respirator Fit Test Requirements & How Technology Can Help

Leaders in Industrial Hygiene

Council for Accreditation in Occupational Hearing Conservation (CAOHC)

Subscribe!

Sign up to receive our industry publications for FREE!